Membrane gas pressure sensor

10 orders of magnitude in challenging environments

Any Light Particle Search

10 orders of magnitude in challenging environments

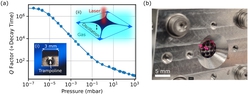

Figure 1: Membrane-based gas pressure sensor. (a) Mechanical quality factor (amplitude decay time) vs gas pressure of the membrane shown in inset (i). (b) Membrane pressure sensor with fiber-optic readout.

Many physics experiments and cutting-edge technologies, such as semiconductor fabrication or quantum computing, require a low-pressure environment, where the amount of air is significantly reduced below the atmospheric level in our surrounding. Accurately measuring the gas pressure in these systems is of central importance.

In the ALPS group, we are developing a novel and highly versatile gas pressure sensor that can potentially benefit a wide range of related applications. At the heart of our sensor is a membrane, shown in inset (i) of Fig. 1(a), which resembles a chip-scale version of a trampoline. Inset (ii) of Fig. 1(a) shows the oscillating trampoline (FEM simulation), which is surrounded by the gas to be measured. Its oscillation is measured interferometrically with an incident laser beam. When excited to oscillate, the time it takes for the trampoline’s oscillation to decay to its equilibrium is highly sensitive to the pressure-dependent friction exerted by surrounding gas particles.

Due to its light and compliant design, in combination with an ultra-low level of intrinsic friction, our sensor can measure all the way from atmospheric pressure down to one ten billionth of atmospheric pressure [1]. This corresponds to a measurement range of ten orders of magnitude, which, to the best of our knowledge, is unprecedented. In contrast to typical pressure sensors, our sensor does not require any calibration, as its behavior can be modelled based on its geometry and material parameters. Furthermore, it is compatible with cryogenic environments, temperatures of several 100°C, other gases than air, magnetic fields, and spatially constrained environments (when combined, e.g., with a compact readout via optical fiber, on-chip photonics, or electronics.

Examples of our current activities include the combination of our sensor with optical fiber readout (Fig. 1(b)) and expanding the measurement capability towards additional gas parameters [2].

References

[1] Reinhardt, C., Masalehdan, H., Croatto, S., Franke, A., Kunze, M. B., Schaffran, J., Sültmann, N., Lindner, A., & Schnabel, R. (2023). Calibration-less gas pressure sensor with a 10-decade measurement range. arXiv preprint arXiv:2309.12044

[2] C. Reinhardt, H. Masalehdan, A. Lindner, and R. Schnabel, Sensor zur Messung von zwei Eigenschaften eines Gases, EU Patent App. EP23167602.4